|

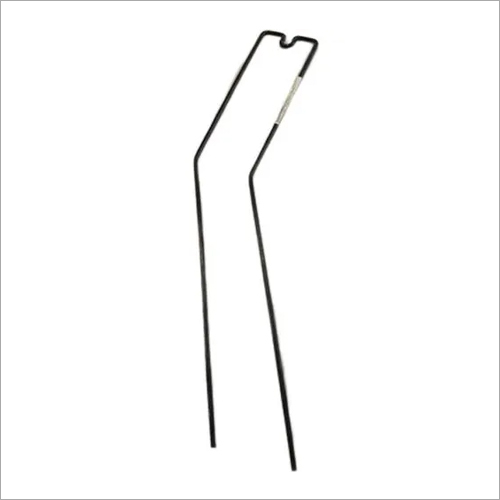

Combine Harvester Tines

MOQ : 1000 Pieces

Combine Harvester Tines Specification

- Diameter

- As per Specification/OEM

- Shape

- Curved/Tine Shaped

- Capacity

- High Durability, Heavy Duty

- Features

- Rust Resistant, High Wear Resistance, Precision Engineered, Easy Installation

- Usage & Applications

- Combine Harvester, Agricultural Machinery, Harvesting Equipment

- Drive Type

- Mechanically Driven

- Lubricating System

- Not Required

- Noise Level

- Negligible

- Size

- Custom/OEM Size

- Surface Finish

- Smooth/Polished

- Product Type

- Machine Parts

- Material

- Metal

- Technology

- Forging

- Power Source

- Tractor Driven

- Surface Treatment

- Coated

- Dimension (L*W*H)

- Standard/As per OEM

- Weight

- Lightweight (Varies by Model)

- Color

- Silver

Combine Harvester Tines Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 15000 Pieces Per Month

- Delivery Time

- 1-2 Days

- Main Domestic Market

- All India

About Combine Harvester Tines

Combine harvester tines are components of a combine harvester that are used for cutting and collecting crops, such as wheat, corn, or soybeans. The tines are typically made of steel and are attached to the cutting bar of the harvester. They work by cutting the crops at the base and lifting them up into the machine for threshing and cleaning. Combine harvester tines come in various sizes and shapes depending on the type of crop being harvested and the specific design of the combine harvester.

Superior Impact and Wear Resistance

Designed for rigorous agricultural work, these tines provide optimized hardness and high tensile strength. Their robust metal composition and smooth, chamfered edges allow for efficient crop handling while resisting wear and deformation, even in challenging harvesting conditions.

OEM Compatibility and Versatile Fitment

Our tines cater to manufacturers and operators, offering precise compatibility with most OEM combine harvesters. Their bolt-on fitment ensures a hassle-free installation and promotes adaptability across different crop types and machinery models, enhancing application versatility.

Precision Engineering for Lasting Performance

Employing advanced forging technology and a rust-resistant coated finish, these tines are engineered for durability and reliability. The refined surface finish minimizes friction and noise, while maintenance-free operation helps maximize uptime for agricultural professionals.

FAQs of Combine Harvester Tines:

Q: How do I install these combine harvester tines on my machinery?

A: These tines are designed with a bolt-on mounting system, making them fitment ready for quick and secure installation on most combine harvesters. Simply align the tine with the mounting points and fasten using standard bolts as per the OEM specifications.Q: What are the advantages of the chamfered edge on these tines?

A: The chamfered edge allows for efficient crop collection by reducing resistance and preventing crop damage. This design enhances overall harvesting performance and contributes to a smoother, more effective operation.Q: Can the tines be used in all types of crop environments?

A: Yes, they are engineered for compatibility with a wide range of crop types. Their high wear resistance, corrosion protection, and optimized hardness ensure reliable operation in diverse agricultural settings.Q: Where are these combine harvester tines manufactured and supplied from?

A: These tines are manufactured, exported, and supplied by a leading distributor and manufacturer based in India. They are available for purchase from traders and suppliers throughout the region and internationally.Q: What surface treatments are applied to increase durability?

A: Each tine undergoes a precision coating process that enhances corrosion resistance and surface hardness, promoting a long service life even under harsh agricultural conditions.Q: What benefits do rust and wear resistance offer for long-term usage?

A: Rust and wear resistance ensure sustained performance, minimizing downtime and replacement costs. This means the tines remain reliable, keeping your harvest uninterrupted season after season.Q: What packaging options are available for shipping these tines?

A: Clients can choose from carton or wooden box packaging according to their requirements, ensuring safe and secure transport of the tines to their destination.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Baler Machine Parts Category

Clamp Iron Parts

Minimum Order Quantity : 1000 Pieces

Surface Treatment : Coated

Weight : 240 Grams (g)

Color : Golden

Material : Iron

Technology : Other,

Dab Patti

Minimum Order Quantity : 1 Piece

Surface Treatment : Coated

Weight : Lightweight

Color : Golden

Material : Metal

Technology : Other, Cold Rolled

Color Coated Baler Tine

Minimum Order Quantity : 1000 Pieces

Surface Treatment : Coated

Weight : 50 Grams (g)

Color : Black

Material : Metal

Technology : Magnetism

Helper Patti

Minimum Order Quantity : 1000 Pieces

Surface Treatment : Coated

Weight : 75 Grams (g)

Color : Black

Material : Mild Steel

Technology : Magnetism

|

MODERN AGRO INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry